Optimizing Production Schedules in a Manufacturing Company

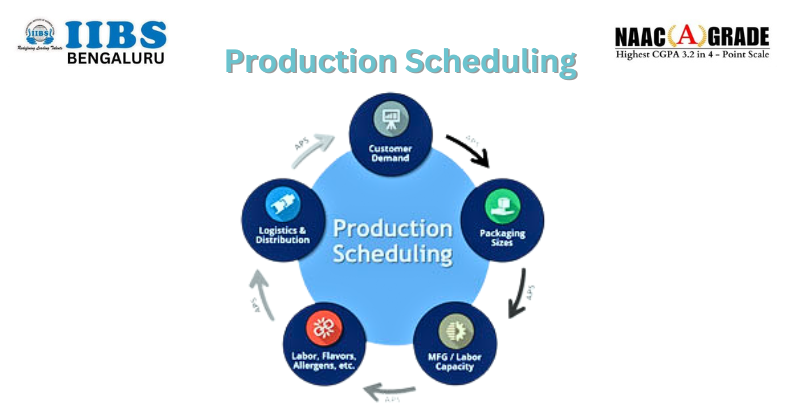

Precision Manufacturing Solutions (PMS), a company specializing in precision engineering components, is facing challenges in optimizing its production schedules. The company operates multiple production lines and faces fluctuations in demand, leading to inefficiencies in resource utilization, longer lead times, and increased production costs.

PMS is considering the implementation of operations research (OR) applications to streamline its production scheduling processes and improve overall operational efficiency.

Company: Precision Manufacturing Solutions (PMS)

Learning Objectives

- How can Precision Manufacturing Solutions utilize operations research techniques, such as linear programming, to optimize its production schedules and resource allocation, considering varying demand patterns and production constraints?

- In the context of production scheduling, how can simulation modeling be applied to assess different scenarios, identify bottlenecks, and evaluate the impact of changes in production parameters on overall efficiency?

Leave a Reply

Your email address will not be published. Required fields are marked *

Apply Now

0 Replies to "Optimizing Production Schedules in a Manufacturing Company"